Covid-19 had a great impact on many businesses . Companies needed to think what their next step was going to be. I acted quickly and reconfigured our manufacturing capabilities at Jewlr to create protective face shields for healthcare workers. We went on to develop our own face shield design and started distributing product to doctors and front line workers within 2 weeks. I was the driving force and figured out what materials were needed and how our operating procedures had to change to meet the new product line. Jewlr provided over 5000 medical workers PPE during the PPE shortage, and our efforts inspired other departments to find other ways the company could contribute in the fight against Covid-19. It was much more then just a CSR campaign.

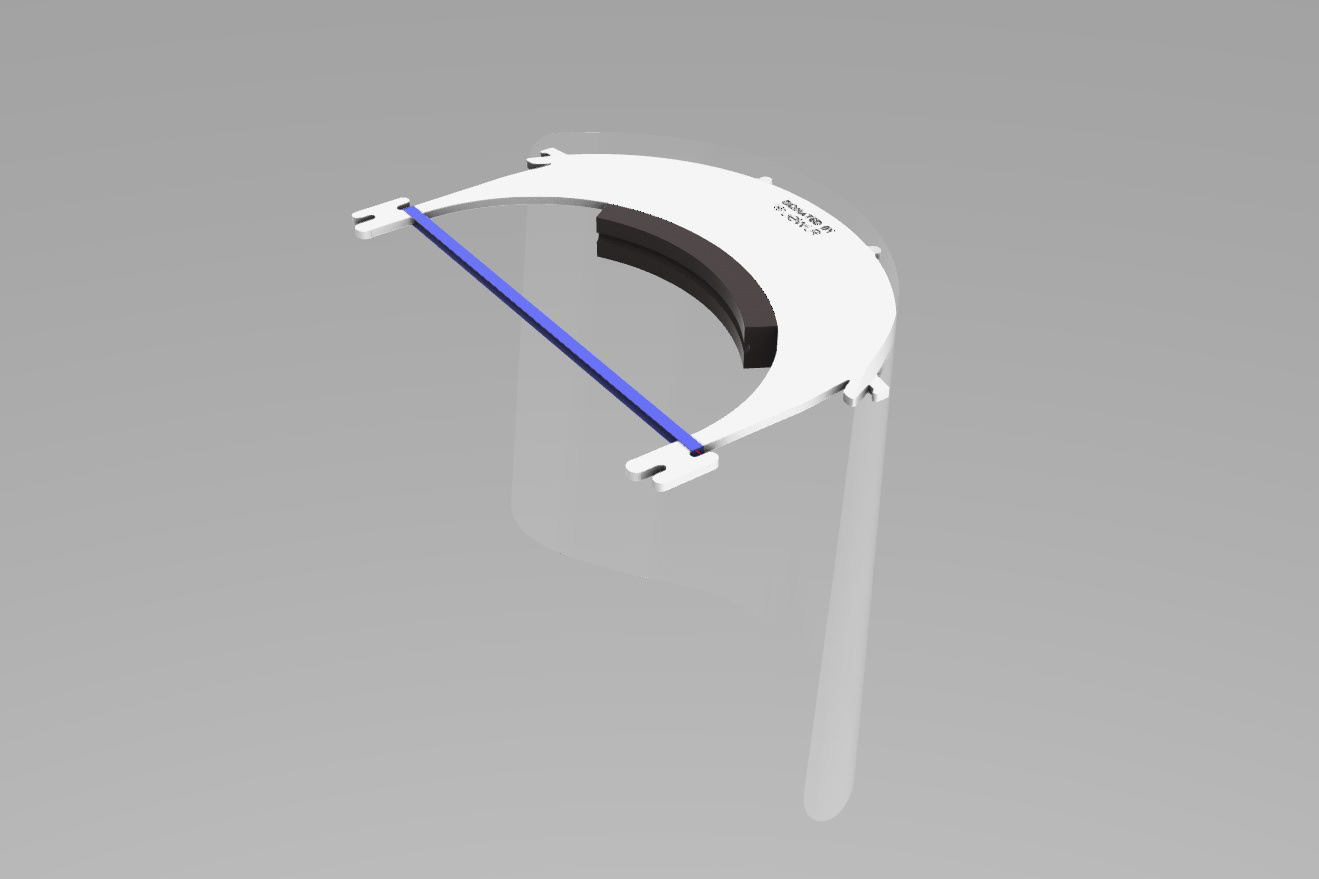

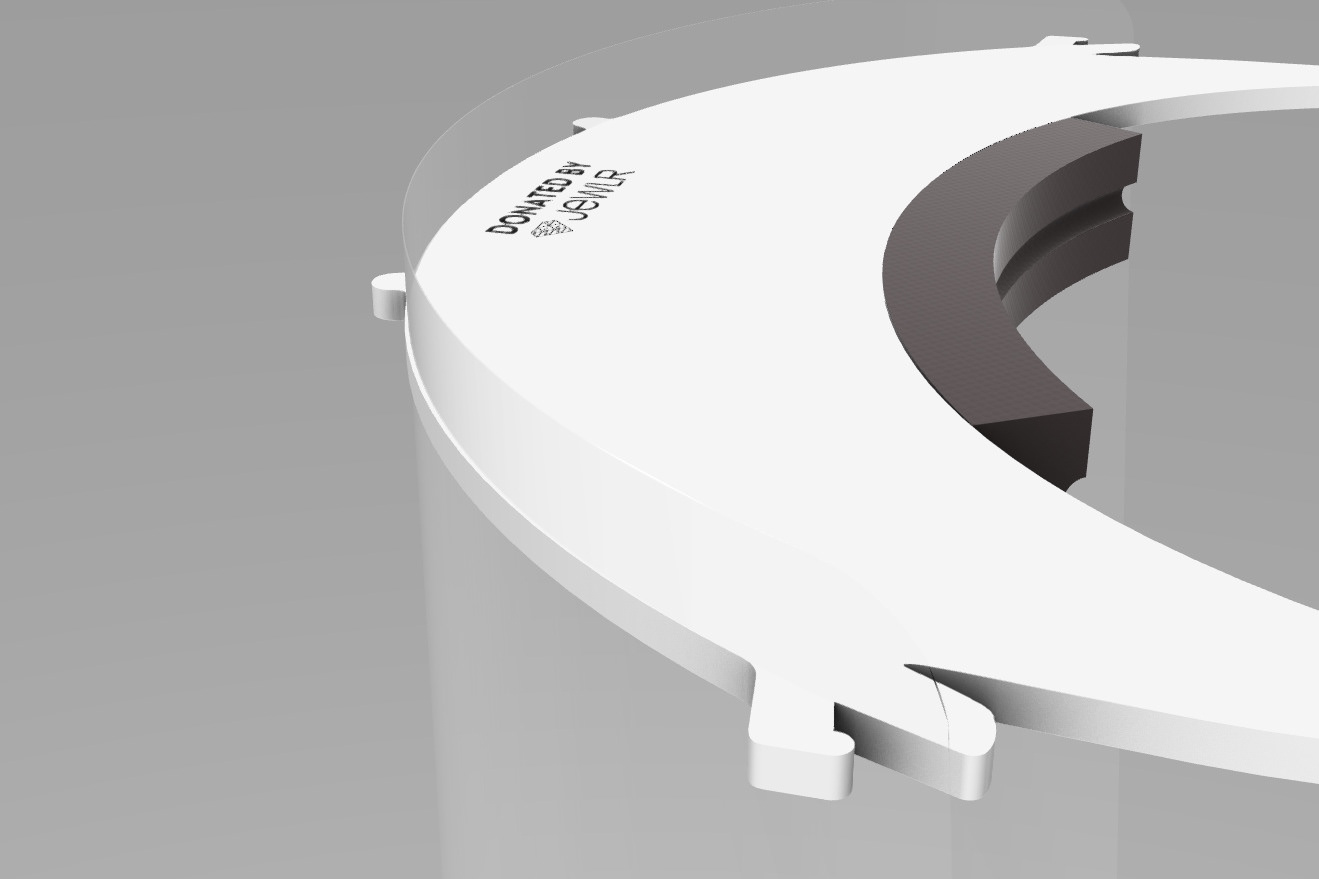

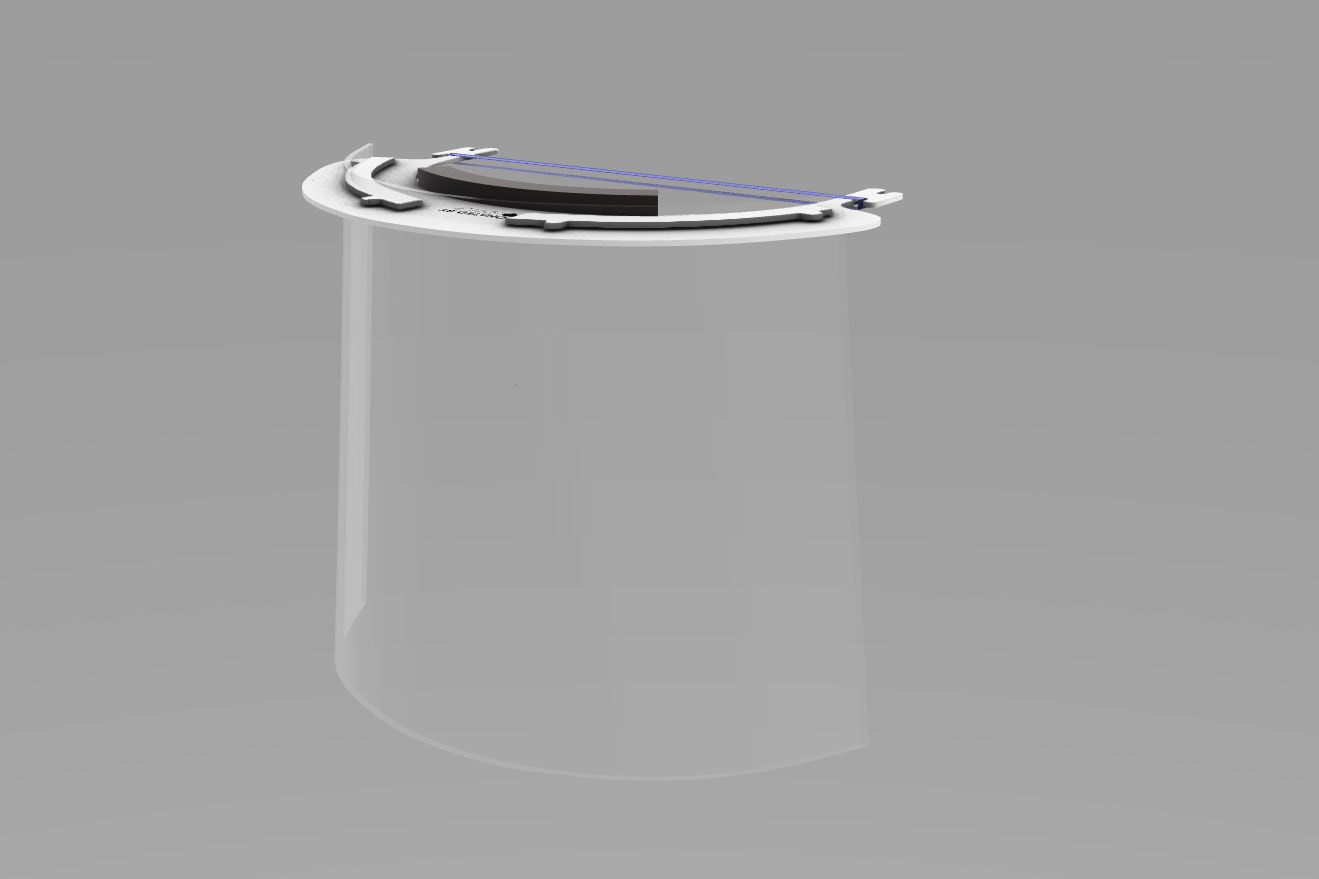

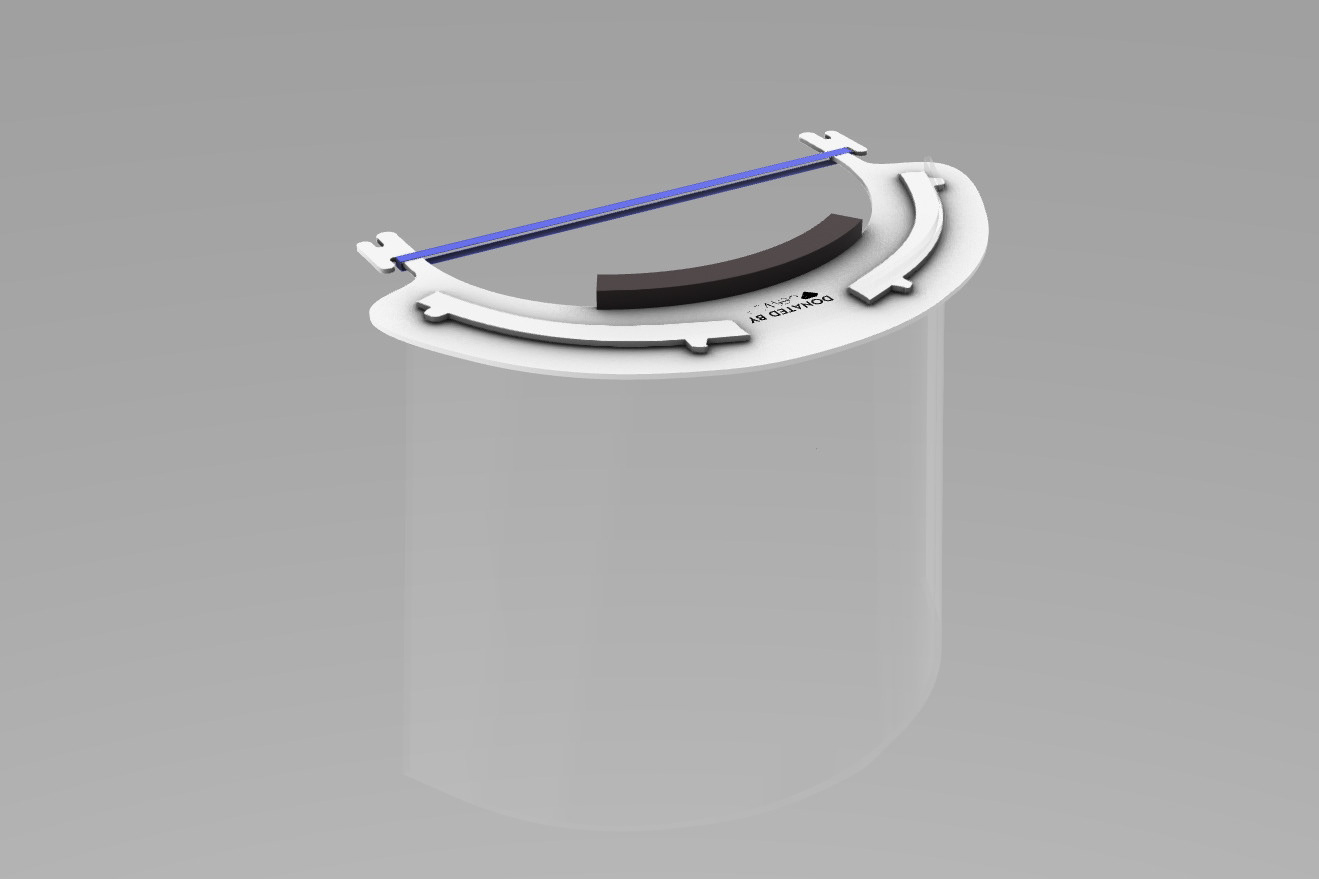

Product Design

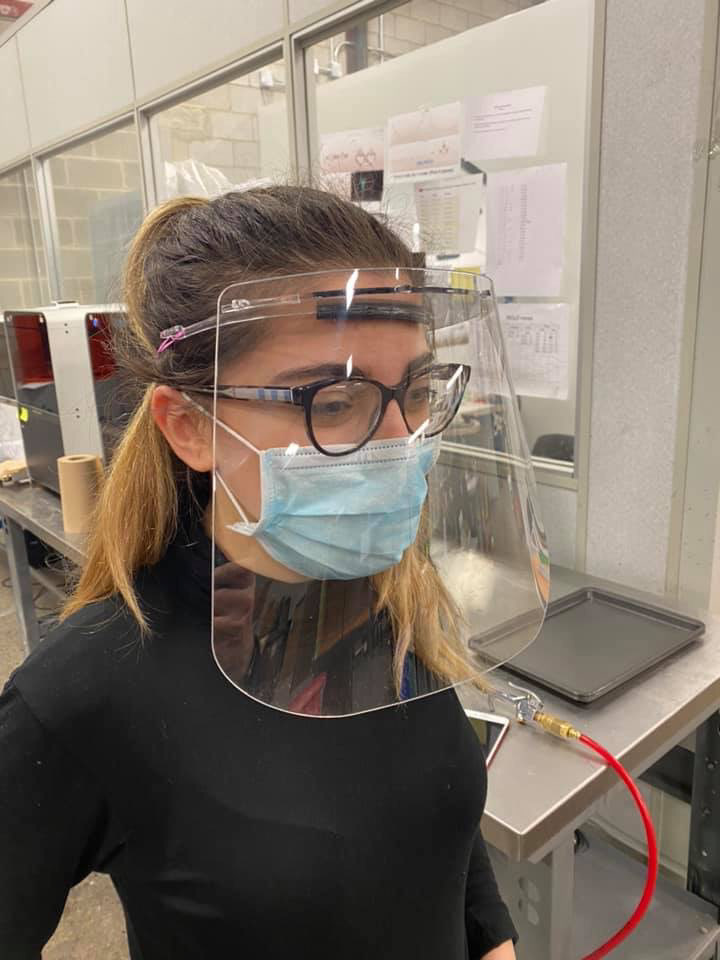

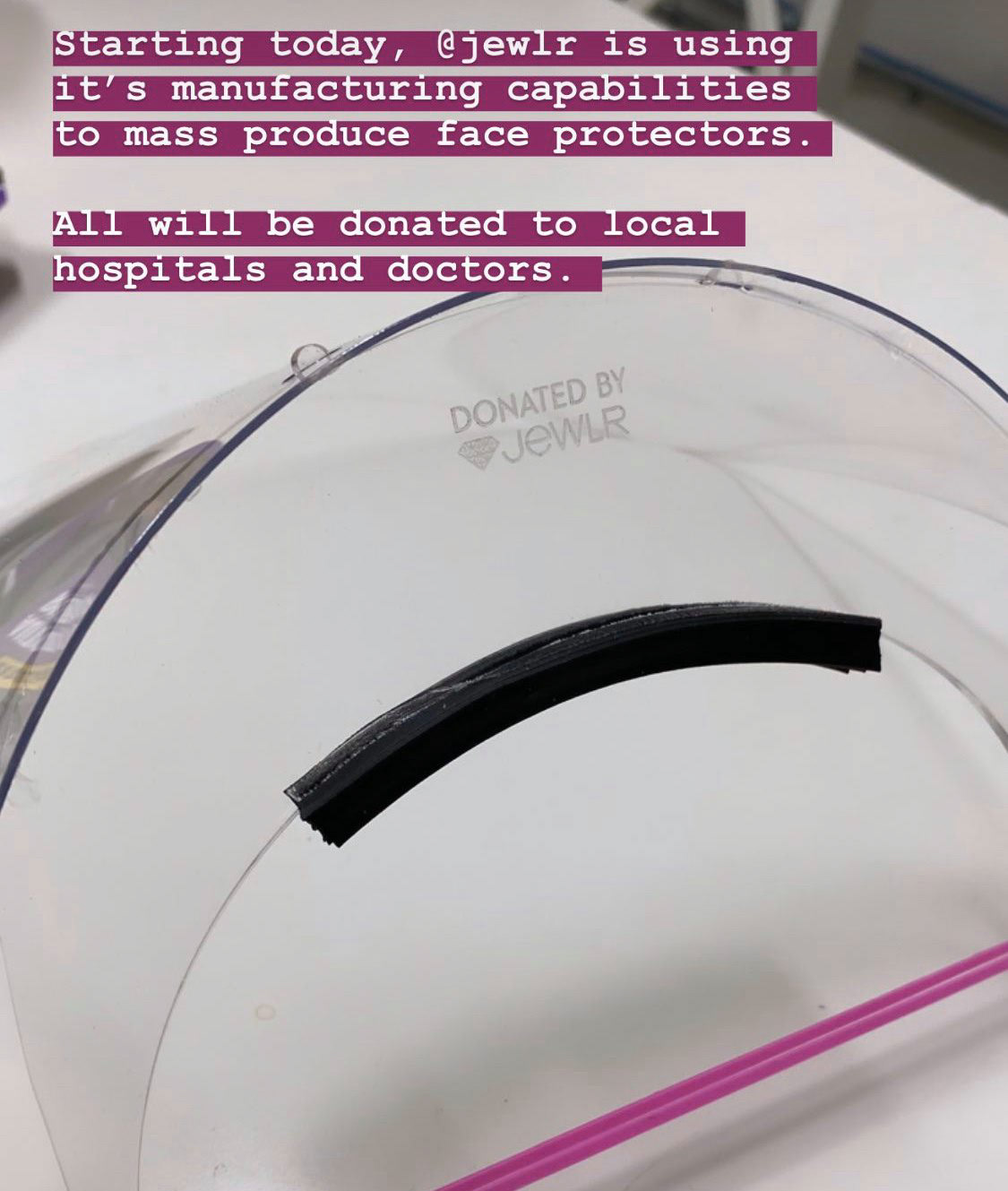

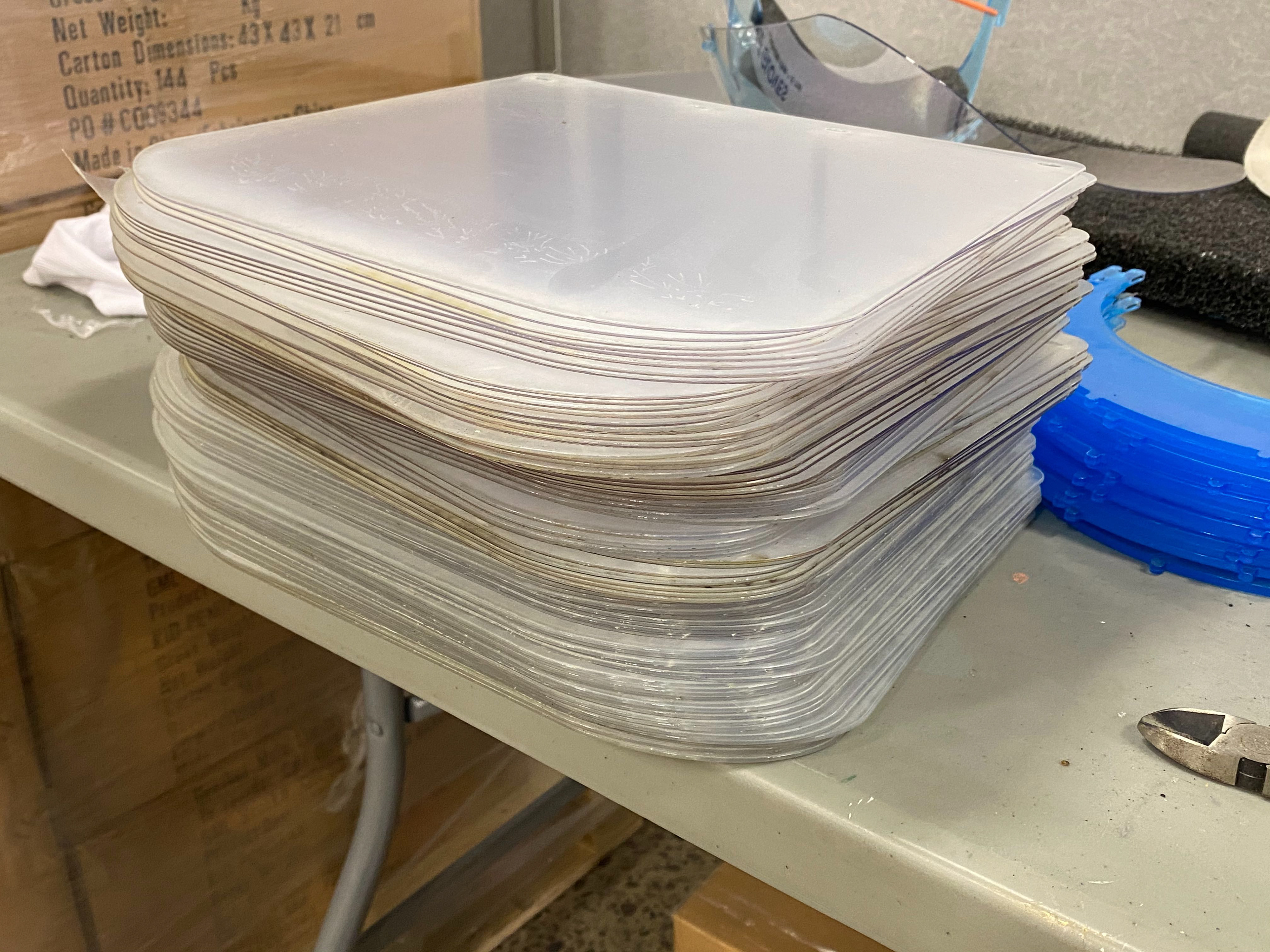

This was the first design of the face shield we began to distribute to hospitals. It was extremely simple to mass produce. We used weather stripping used in car doors that can be purchased at any home depot to provide padding on the forehead. We used rubber thick rubber bands as a head strap because it very affordable and easy for to get, at the time elastic material was in short supply so this was a way to overcome this issue. The design was very simple to assemble and required no skilled labour to assemble and each piece was engraved with the Jewlr logo.

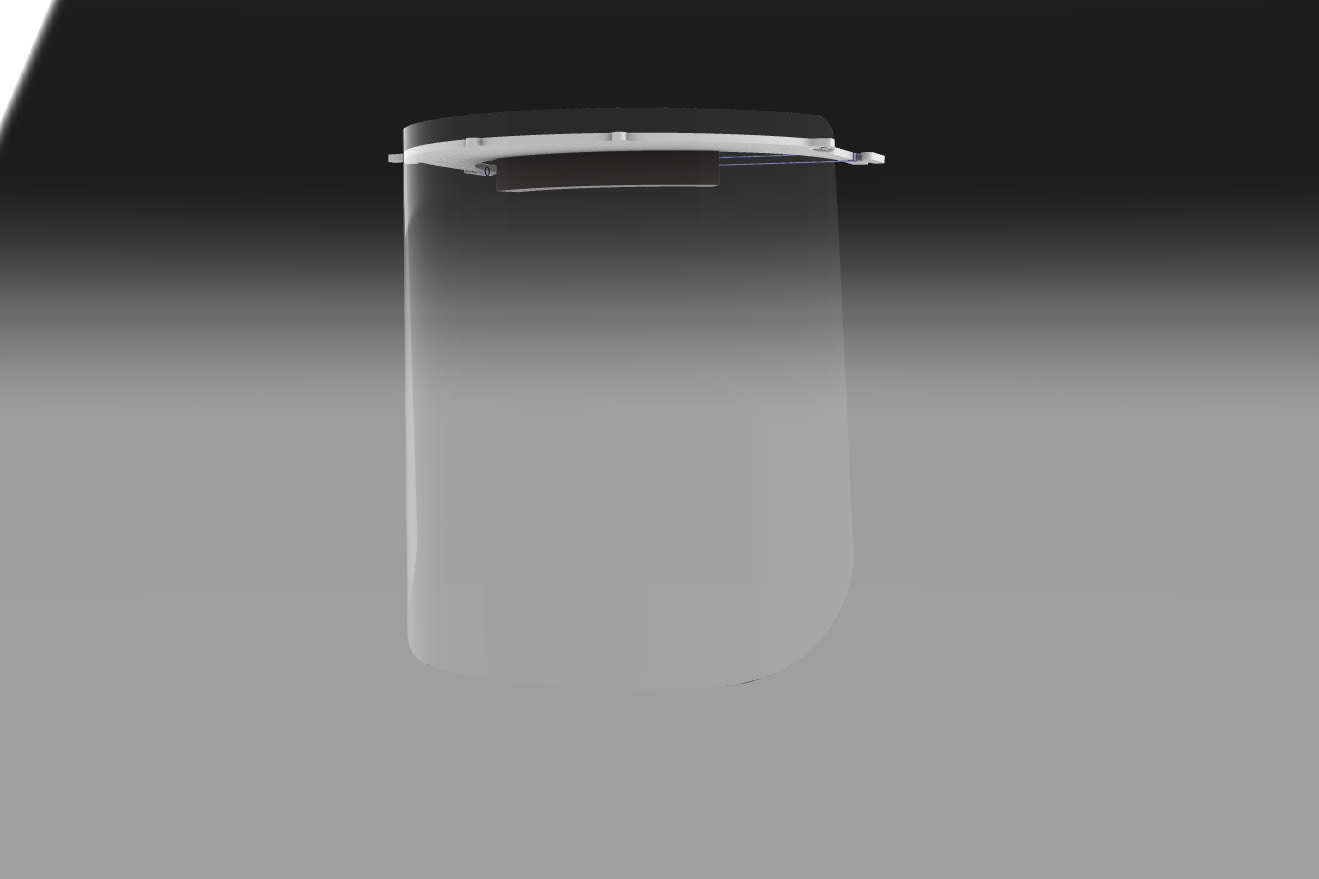

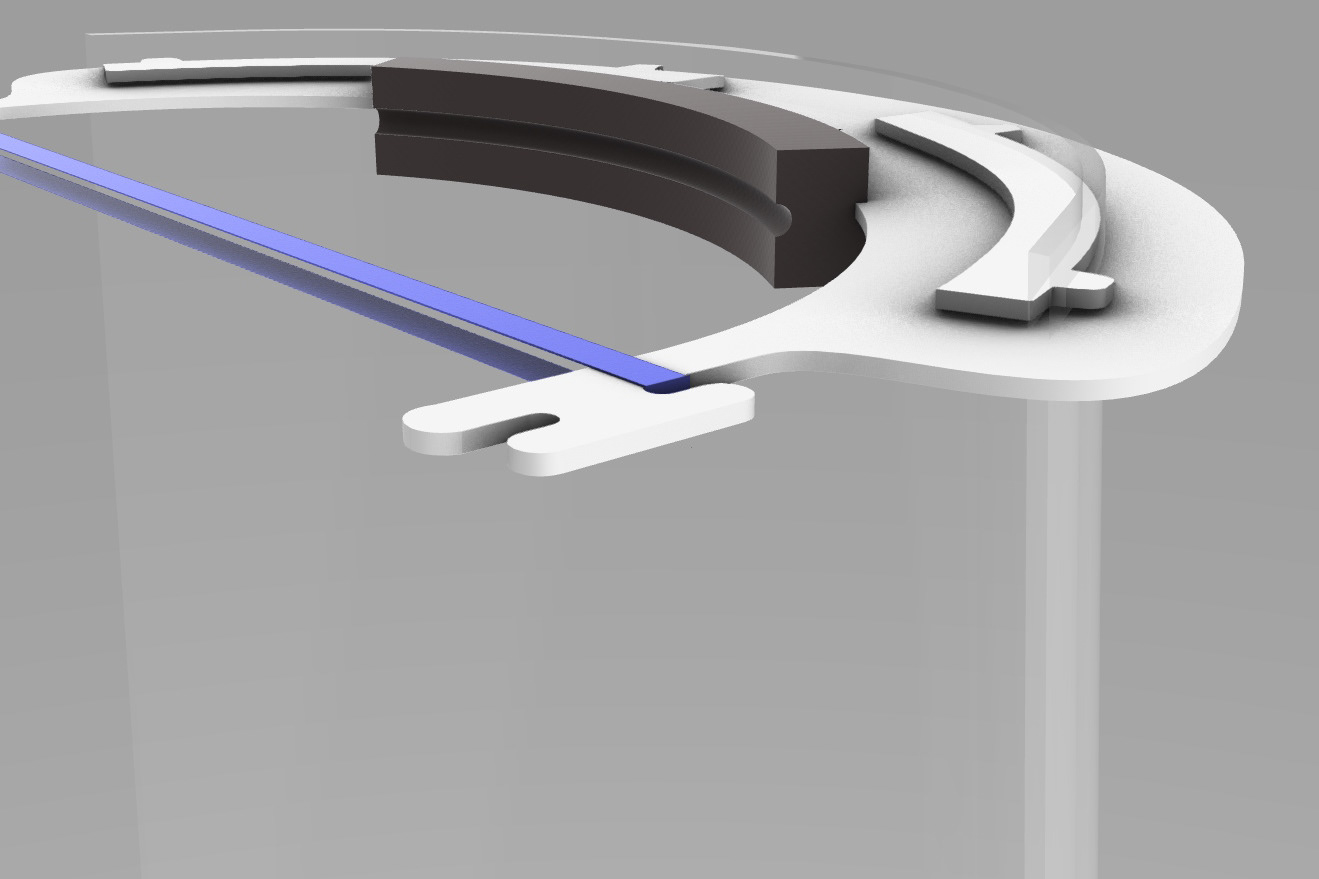

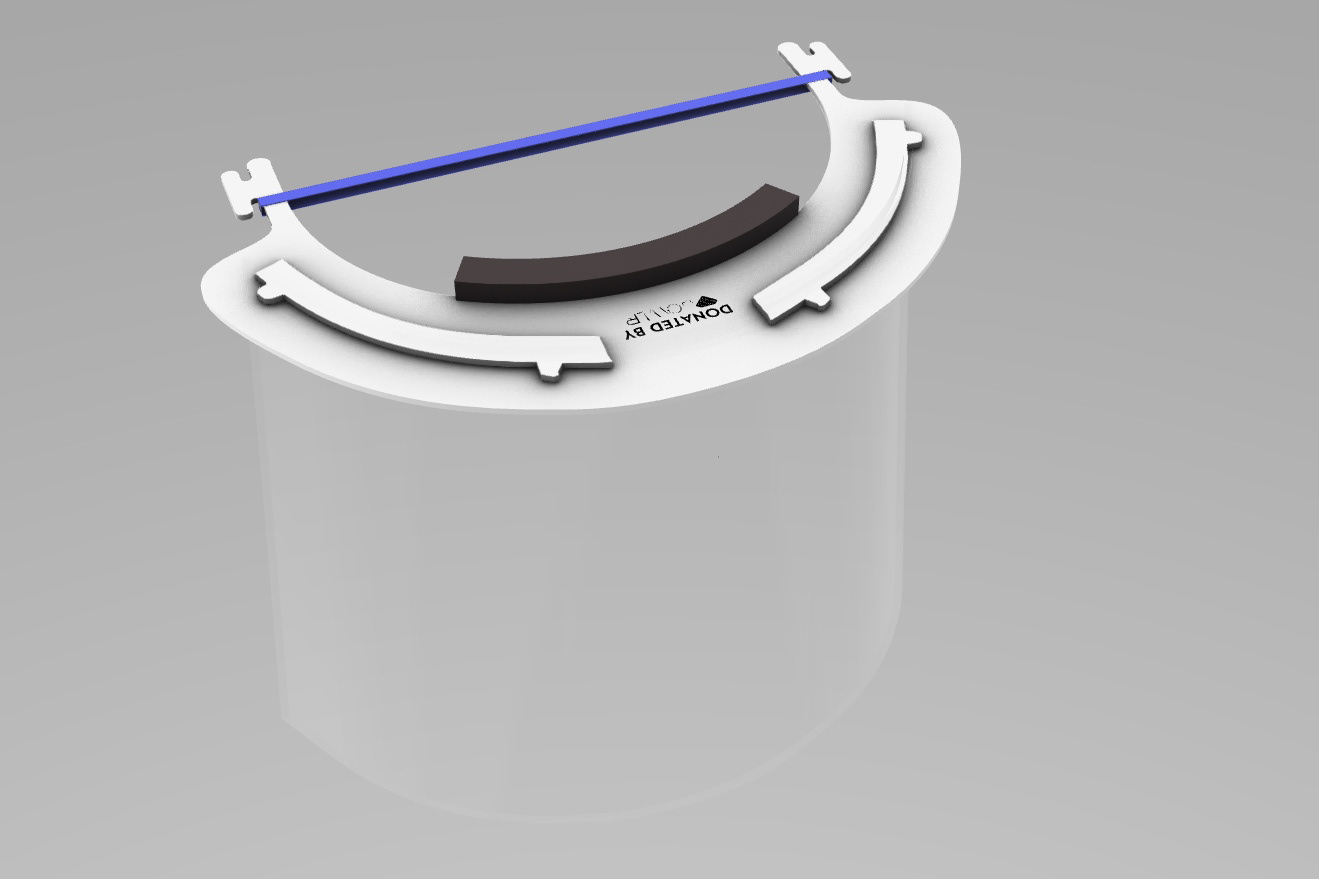

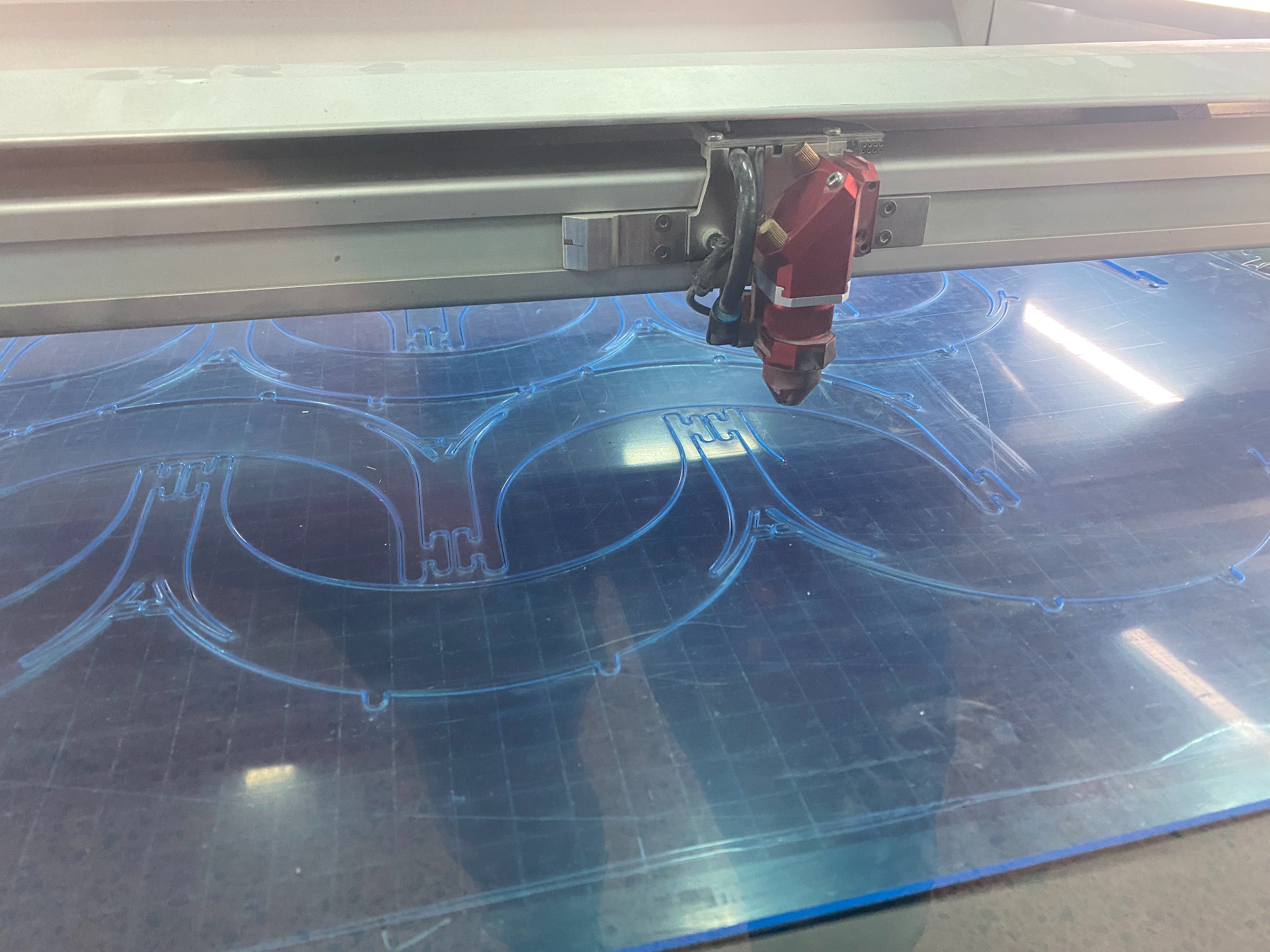

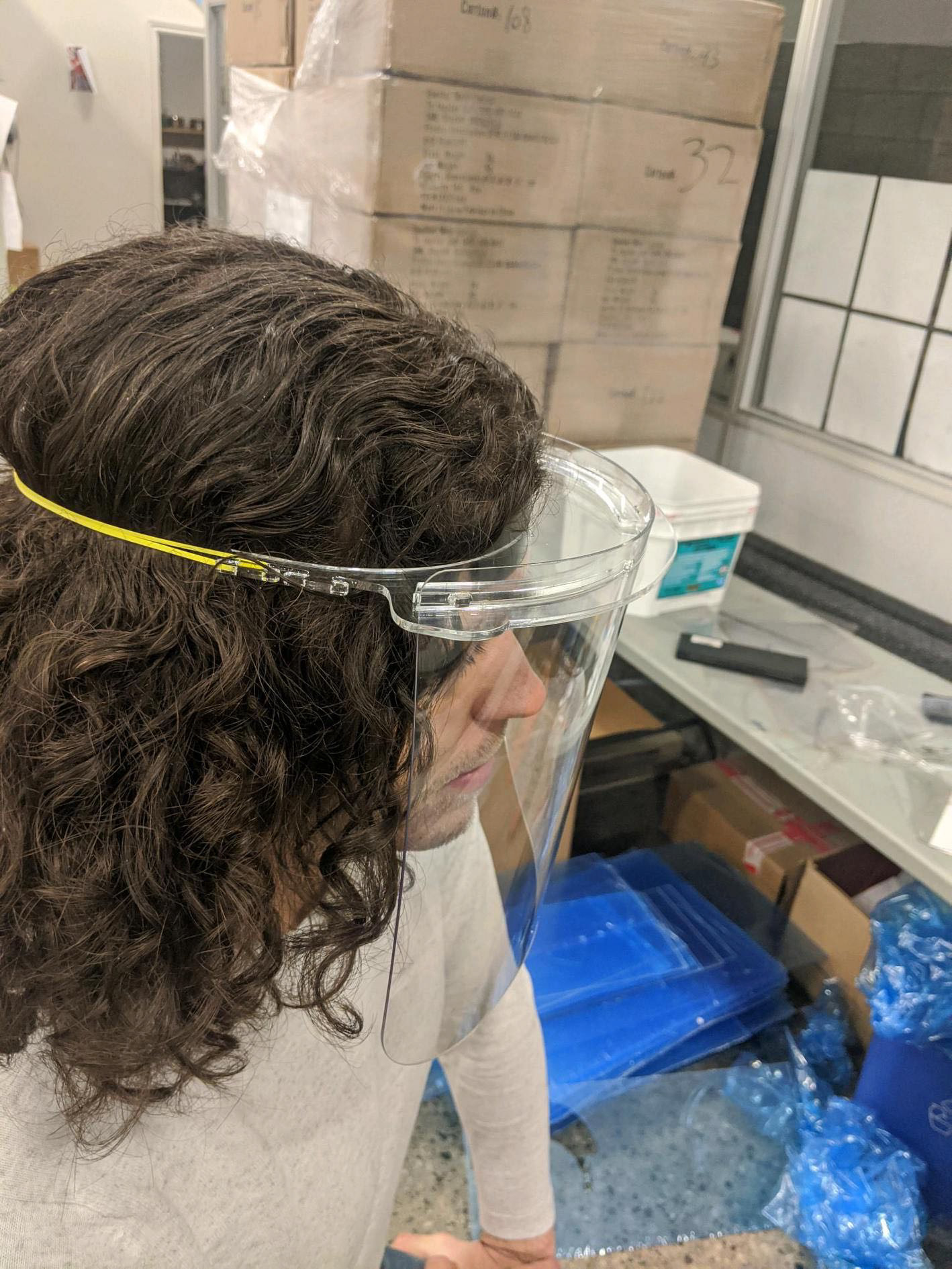

This is the second iteration of the Jewlr Face shield. We had to change our design because precure the PET material we were using for front visor was no longer available after Donald trump created policies to limit the export materials used to make PPE from the USA. We over came this issue by creating a slot for the visor to slid into and a bracket system that held everything in place. We had to iterate quickly but in the end this new design was 15% faster to produce on the CNC laser.

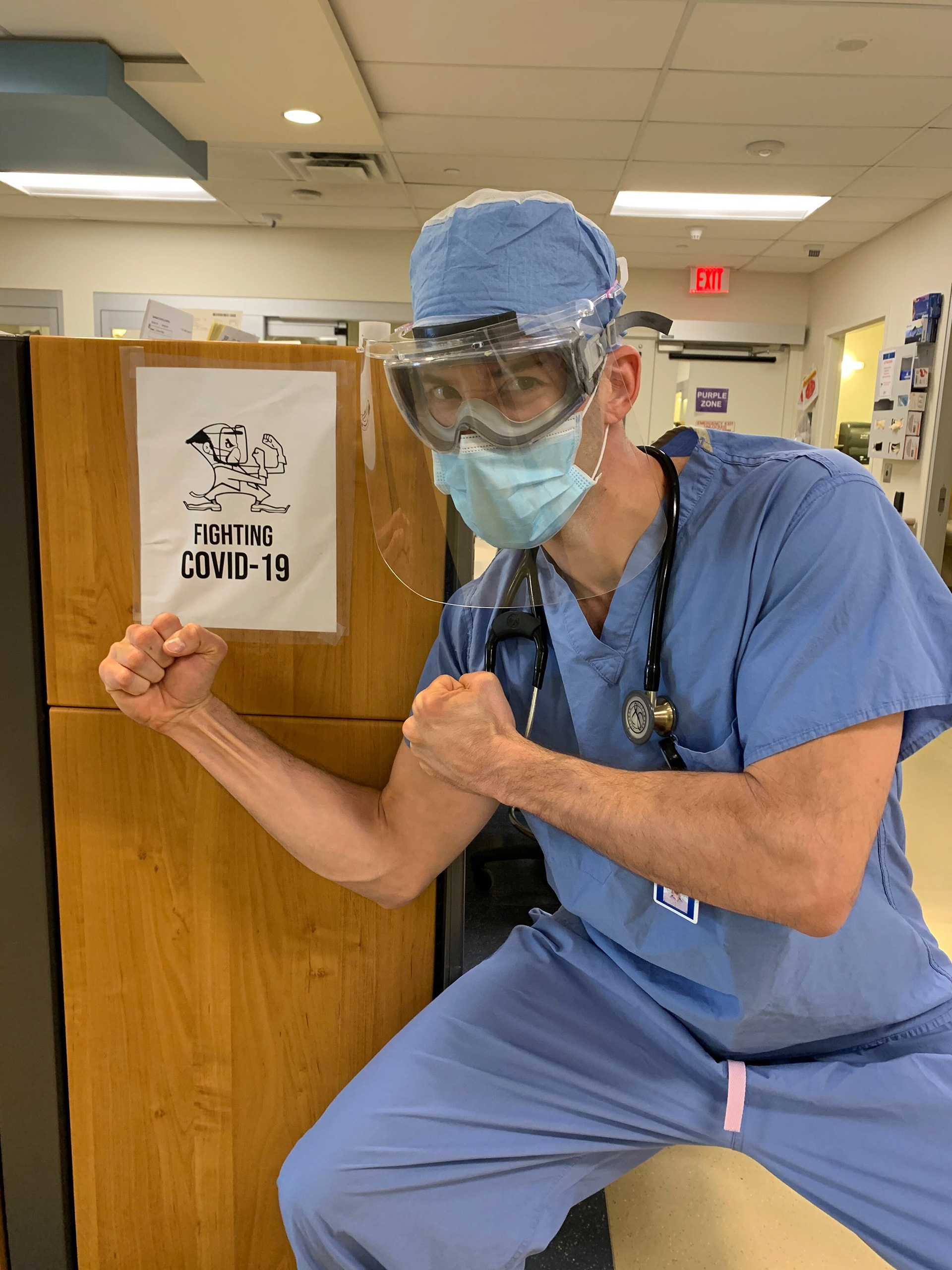

Front Line Photos

MEDIA

The face shield project received lots recognition from multiples sources. Our efforts were discussed on the CBC radio show Ontario Morning. Here are some online blogs that highlighted our efforts.

Project Showcase